DWC

INTRODUCTION TO

DWC is a double layer pipe with the outer layer having corrugation and the inner layer with a smooth surface. The outer corrugated layer substantially increases the stiffness of the pipe, which enables the pipe to take same burial load at a fraction of the weight of Solid wall pipes of the same size.

DWC is a double layer pipe with the outer layer having corrugation and the inner layer with a smooth surface. The outer corrugated layer substantially increases the stiffness of the pipe, which enables the pipe to take same burial load at a fraction of the weight of Solid wall pipes of the same size.![]() system incorporates Integrated Coupling system with elastomeric seal ring for leak tight joining.

system incorporates Integrated Coupling system with elastomeric seal ring for leak tight joining.

![]() is a technically superior and cost effective solution for drainage and sewerage systems over conventional DI & RCC pipes with a steep reduction in installation time and equipment hiring cost. These pipes are available in sizes ranging from 100mm DN/ID to 1200mm DN/ID having ring stiffness ranging from SN2.5 to SN16. Inner layer can be in different colours, with the outer layer in black colour.

is a technically superior and cost effective solution for drainage and sewerage systems over conventional DI & RCC pipes with a steep reduction in installation time and equipment hiring cost. These pipes are available in sizes ranging from 100mm DN/ID to 1200mm DN/ID having ring stiffness ranging from SN2.5 to SN16. Inner layer can be in different colours, with the outer layer in black colour.

![]() are manufactured as per following standards.

are manufactured as per following standards.

- IS 16098 Part II

- ISO-21138 Part III

- IS-14930

- BS EN 50086

FEATURES & ADVANTAGES

-

Longer Length

These pipes are available in 6m/12m length. Thus, the numbers of joints are less, resulting in faster installation.

-

Smooth Inner Surface

Offers least resistance to flow. Improves flow characteristics.

-

Lightweight

Easy to handle, transport and install. 70-90% weight reduction compared to DI/RCC pipe.

-

High Impact Strength

Does not dent/break during handling, transport and installation.

-

Long Service Life

Due to inherent advantages of no corrosion and shedding sudden overload by temporary deformation and recovery, these pipes have long service life,compared to conventional piping material.

-

Low Installation Cost

Installation cost is low on account of speedy jointing method, requiring no foreign material for jointing. Less trench width required, resulting in low civil work cost.

-

Deformation

Allows deformation and soil movement, which won’t damage structure under external load,unlike rigid pipes.

-

Chemically Inert

Does not corrode. Remains unaffected by gases/acid formed in sewers and chemicals present in sewage.

-

High Abrasion Resistance

Due to high abrasion resistance, wear and tear is low. Thus,last longer.

-

Ease in Jointing

Due to integrated coupling system with elastomeric sealing ring, the process of jointing is fast and joints are leak-proof.

-

Life Cycle Cost

Due to low product weight, low installation cost, least maintenance and longer life, life cycle cost is least.

-

Recyclable

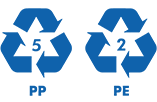

100% Recyclable

Applications

Sewer Line Application

Drainage System

Rainwater Drainage

Highway Drainage Corridors

Storm Water Drainage

Effluent Discharge

Irrigation System

Ducting

QUALITY TESTS PERFORMED

- Density Test

- Mass Melt Flow Rate Test

- Ring Flexibility

- Ring Stiffness

- Impact Strength

- Water Tightness

- Thermal Stability

- Creep Ratio (Oxidation Induction Test)

JOINTING SYSTEM

Sealing ring plays a vital role in making joints leak-proof.

Elastomeric Sealing Rubber Ring

- Elastomeric sealing ring made of EPDM with resistance to UV exposure, ozone, ageing, weathering, and many chemicals great for outdoor application.

- Low electrical conductivity

- Resistance to steam and water

- Surface of the ring is smooth, free from pitting cracks, blisters, air marks, and any other imperfection that may affect its behavior in service

- Elastomeric sealing rings are made in accordance with one of the type (Type 1 to Type 6) of IS 5382 standard.

The jointing procedure of DWC pipes is easy and simple to adopt and is illustrated below.

-

-

Sealing Ring

-

Put ring in first corrugation valley.

-

Fixing of ring

-

Ensure ring is well fitted on pipe

-

Arrangement for joining

-

Bring pipe closer as shown with joining device

-

Pipes are now successfully jointed and are 100% leak-proof